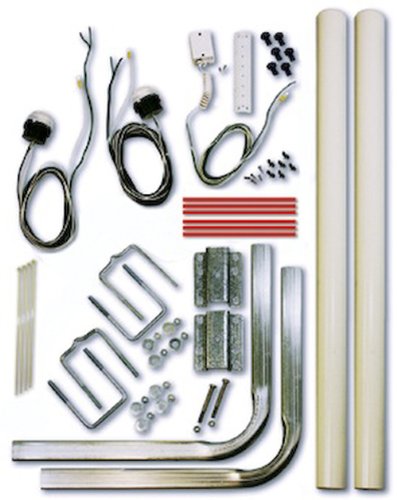

Buy K & N 69-4518TTK Performance Intake Kit

Buy K & N 69-4518TTK Performance Intake KitK & N 69-4518TTK Performance Intake Kit Product Description:

- Black color

- Estimated horse power gain of 12.22 horse power at 4600 RPM

- Reduces intake restriction resulting in additional power and torque

- Million mile limited warranty

- Not legal for use in California and other states adopting California emission standards

Product Description

Built for performance and show, the 69 Series Typhoon Air Intake System is a free flowing mandrel bent aluminum tube induction system designed to fit many sport compact performance vehicles. Typhoon intakes come in one of three designs as cold air intakes (CA), short ram intakes (SR), or complete cold air (CCA) intakes which can be configured as either a cold air intake or a short ram intake. Some Typhoon's have high quality finish options including polished aluminum, powder coated red, and powder coated silver among others. K&N intake systems replace your vehicle's restrictive factory air filter and air intake housing. K&N intakes are designed to dramatically reduce intake restriction resulting in additional power and torque. All of them come with a Million mile limited warranty and are guaranteed to increase horsepower. Some Typhoon air intakes are not legal for use in california and other states adopting california emission standards while others are CARB exempt and 50 state legal.

Customer Reviews

Most helpful customer reviews

4 of 4 people found the following review helpful.

Exaclty what I wanted! More than expected!

Exaclty what I wanted! More than expected!

By B. Speer

After much debate and teetering on the idea of closing on this, I took the leap. I have no regrets! I have a turbocharged 2009 Chevrolet Cobalt SS and there were actually quite a few options in the realm of intakes. Perhaps I was partial to K&N because I had one in my last car, yet I feel I got the best deal for the money. Amazon had it the cheapest by far and much praise be due to them for their rapid processing and shipping.When I ordered it I really was just going for the performance gains in the future once I got tuned for it and other modifications. However, much to my surprise I saw a jump in my boost and top-end HP. K&N had a dyno sheet backing the claim of improved performance and they weren't lying.All in all, I could not be happier with not only the product but all around great service. From shopping-to-ordering-to-delivery, it was all simple and exactly what I ask for.

0 of 0 people found the following review helpful.

Don't install without a tune. +11% LTFT. "Meh" quality and fitment, but awesome for sound

Don't install without a tune. +11% LTFT. "Meh" quality and fitment, but awesome for sound

By Charlie

UPDATE 10 MAY 2013:I purchased HP Tuner's VCM Suite with the Pro Interface for GM Cars and was able to dial in the MAF to get a LTFT that varies between -0.8% to +0.8% which is a remarkable difference from +11% to +12%. The engine idles a LOT smoother and it runs better. I would HIGHLY recommend you get a custom dyno tune if you're not comfortable tuning it yourself, or to consider the HP Tuner VCM Suite to tune it yourself. Either way, this K&N intake will require a tune.UPDATE 3 MAY 2013:The long term fuel trim readings are climbing well over +11%, indicating a very lean condition. A tune is required for safe operation of the engine!!K&N Typhoon Short Ram Intake for 08-10 Cobalt SS Turbocharged (69-4518TTK)I will break up this review into 2 sections. The first will focus on my review of the kit, the second will focus on the installation along with some helpful tips.REVIEW:---------------------------------------------------------------------------The Short Ram Intake (SRI) is not intended to be a true cold air intake (CAI), although they look similar and are often marketed interchangeably. The CAI's for the Cobalt SS Turbo are all designed to have the conical filter mounted inside the fender (where the snorkel is located) which allows for easy water intrusion and makes it difficult to check the filter. The SRI can be subject to more hot air ingestion although once you are moving, the inlet temperatures drop significantly.The general consensus is that the K&N SRI is the best option for the Cobalt SS TC. I found the overall quality to be mediocre, average at best. This is mainly because the air inlet pipe is made of very thin and soft aluminum. Rather than a single mandrel bent pipe, it is comprised of multiple sections welded together, then powdercoated. The majority of us found the turbo inlet side to have been dented right out of the box. K&N also gives a mix of stainless fastners, and non-stainless washers which makes no sense. The hose clamps are also standard Breeze clamps with non-stainless screws with stainless bands. I spent a few dollars to buy stainless washers and all-stainless Ideal-Tridon Series 65E liner clamps to prevent the worm gear slots from cutting into the conical filter or silicone coupler. The extra parts I bought (which aren't necessary but just something I like to do as an engineer): Ideal-Tridon Series 65E liner clamps in #36 (qty 2), #52 (qty 1). 5/16" stainless washers (qty 10), ¼" stainless split lock washers (qty 1), ¼"x1" stainless fender washers (qty 2), ¼" stainless washers (qty 6). I opted for the less expensive 18-8 stainless that isn't made to any specification/standard.The other complaint I have is that K&N, as an engineering company, doesn't do a good job with the engineering part. There are no torque values provided for ANY of the fasteners. In addition, the fitment isn't very good and isn't explained very well in the instructions. The PCV/crankcase vent nipple is made out of plastic and in its location, makes for a VERY tight fit. The air conditioning high pressure port is also within a few millimeters of the air inlet pipe.K&N also claims no tuning is required, and I've been in the "must tune" crowd for over a decade with my Ford intakes. However, I opted to give this a try since tuning the Cobalt SS Turbo seems to be far more complex than Ford's system and SCT doesn't support the SS Turbo, so I am out of luck with using my Advantage/Pro Racer Package. I datalogged the Cobalt in stock form, and then datalogged it with the K&N. In stock form, the Short Term Fuel Trim (STFT) varied from -5.47% up to +11.72% (caveat is that I only warmed it up and revved it in the garage). With the K&N filter installed, the STFT varied from -7.81% to +13.28% with a peak LTFT of +9.38% - and this time I took it out on the road and drove it like I would normally drive it. In comparison with my other modified Fords, it is about the same.The biggest change you will notice is the sound. The Cobalt SS TC uses a Bosch direct fuel injection system that makes a bunch of odd noises during a cold start, namely a growl from the high pressure fuel pump and then followed by a loud tick-tick-tick when the fuel pressure steadies at 300-500 psi idle. However, with the K&N SRI installed, you will hear a much louder growling upon startup. Once warmed up, it quiets down until you open the throttle at which point a loud sucking sound will occur followed by a WHOOSH when the throttle is closed. Once on the road, anytime the throttle is opened and the turbo spools up, it will be audible from inside the car.The heat shield isn't a great fit. I found it to contact the fender of the car. I used a piece of old coolant hose cut away to act as a bumper. K&N only designed the shield with a bumper that sits over the engine mount and just ignored the other side of the shield that rests directly on the painted fender!There is also controversy about how to orient the conical filter. Many say to rotate the metal strip so that it sits at a "11:30" position, whatever that is. I looked closely at my filter and oriented the largest part of the offset so that it is directly perpendicular to the MAF sensor. Others have suggested rotating the offset so that it sits straight up. This apparently impacts the air turbulence/impact on the MAF sensor which can skew the fuel trims.My overall score for the kit: 4.0 stars out of 5 stars. K&N was sloppy with the engineering of this kit, but probably because there is a very very small density of SS Turbo cars on the market and there is very little profit to be made from this particular vehicle. I used a tail pipe expander and a small hammer to correct the dents.PROS: Changes the sound and behavior of the engine/turbo, it will be LOUD. It is audible from a block away in a quiet neighborhood.CONS: VERY tight fit, some non-stainless parts included in the kit, requires some adjustments to fit properly, quality isn't there.INSTALLATION----------------------------------------------------------------------------Tools needed:3/8" drive ratchet¼" drive ratchet3/8" drive extension bars, x1¼" drive extension bars, x23/8" drive, 10mm long socket¼" drive, 5/16" socket3mm allen key / allen socket3/8" drive 4mm allen socket5/8" or 16mm combination wrenchT-30 Torx BitExtra parts needed:Nothing mandatory, but I opted to convert all the hardware over to stainless steelIdeal-Tridon Series 65E liner clamps in #36 (qty 2)Ideal-Tridon Series 65E liner clamps in #52 (qty 1).5/16" stainless washers (qty 10)¼" stainless split lock washers (qty 1)¼"x1" stainless fender washers (qty 2)¼" stainless washers (qty 6).I opted for the less expensive 18-8 stainless that isn't made to any specification/standard.Materials needed:Blue threadlocker (included in the K&N kit)Permatex pipe thread sealantBrake cleaner / contact cleaner / denatured alcoholThe K&N instructions have tiny, low detail photographs. They fail to mention the need for a T-30 torx bit to remove the forward isolator of the stock airbox. The OEM MAF screws are torqued to 0.6 N-m, and the OEM airbox nuts are torqued to 1.5 N-m according to the GM service manual. I found that 6mm/M6 18-8 stainless screws have a maximum recommended torque of 7.8 N-m with lube, and that 4mm/M4 18-8 is rated at a max of 2.3 N-m.If you have an engine ID plate, the T-bracket should be moved as close to the firewall as possible. This allows the pipe to actually bolt to the T-bracket. I used 6 5/16" washers on the fender-side airbox stud, while 4 5/16" washers were used on the engine-side airbox stud. The included spacers are not stainless and are not thick enough. I also cut a piece of old coolant hose to pad the bottom of the heat shield at the fender side because it would vibrate against the painted fender.I would install the crankcase nipple last, and I used some pipe thread sealant on the threads to provide more sealing. The MAF screws should be "good-n-tight" with a 3mm allen key, I hate not having a torque spec but the aluminum threads aren't really designed to handle a lot of torque.Install the silicone coupler on the pipe with just enough silicone to allow the hose clamp width to seat fully on the pipe. The rest of the coupler will fit over the turbo inlet. Allow some clearance to adjust the pipe so that it clears the A/C high side port.I torqued the T-bracket button-head screws to 5.31 N-m with blue threadlocker. I torqued the bolts attached to the heat shield / fender to 7.79 N-m. The airbox stud nuts were torqued to 5.31 N-m with blue threadlocker. I torqued the bolt that attaches the pipe to the T-bracket to 5.31 N-m with blue threadlocker. I also used blue threadlocker on the MAF screws.The crankcase vent tube is a VERY tight fit on the nipple. Be aware if it ever cracks or breaks.

0 of 0 people found the following review helpful.

Whoosh!

Whoosh!

By Dr. Georg Groeber

First of all, my package arrived all busted up. The metal tube that runs from the turbo to the filter was bent and I had to send it back. Not sure who is to blame for this. Not me. Anyway, once I finally installed this...WHOOSH! LOVE IT! I can't "feel" any power gains but, oh...how it has changed the demeanor of my Cobalt SS Turbo. I can finally hear the turbo working and it is a thrill. The not-over-the-top whoosh mixed with the angry little snarl from the exhaust has created a small-displacement symphony to my ears. WHOOSH!

See all 3 customer reviews...Latest Price:

See on Amazon.com!

More Info:

See on Amazon.com!

See Customers Review:

See on Amazon.com!

![]() Awesome!

Awesome!![]() Have arthritis? Don't buy this. Otherwise; Great buy!

Have arthritis? Don't buy this. Otherwise; Great buy!![]() Sony VAIO

Sony VAIO